Zeramex Digital Solutions

Competence centre for customized prosthetic solutions Made in Switzerland

Product Range

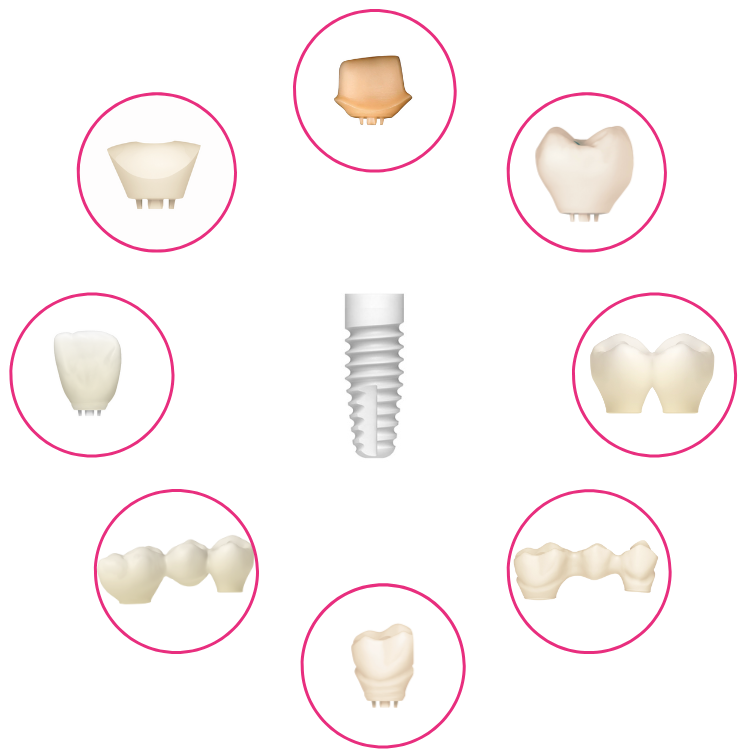

In addition to customised abutments and monolithic crowns with a Zeramex XT implant connection, the Swiss competence centre Zeramex Digital Solutions offers you a service for the preparation of your digital data or for finishing the prefabricated raw restoration.

Products & services at a glance

- Fully customised gingiva formers and abutments

- Fully customised monolithic crowns and bridges

- Customised crowns for Zerabase X with or without screw hole

- Monolithic crowns and bridges with implant connection (also as a cutback solution)

- Colouring & glazing

- Customised design development

- 3D models OK/UK (without replica)

- Virtual model design based on intraoral scan data

The restorations are made of yttrium-stabilised zirconium dioxide (Y-TZP) and can be ordered in the various Vita colours (A1-A4, B1-B4, C1-C4, D2-D4) and in different translucencies - also as a multilayer.

> Product range Zeramex Digital Solutions (PDF)

> Prosthetic possibilities with Zeramex XT (Video)

Case documentation by Dr. Dr. Thomas Mehnert

Adhesive Base Zerabase X

Zerabase X – the CAD/CAM alternative for laboratory & chairside

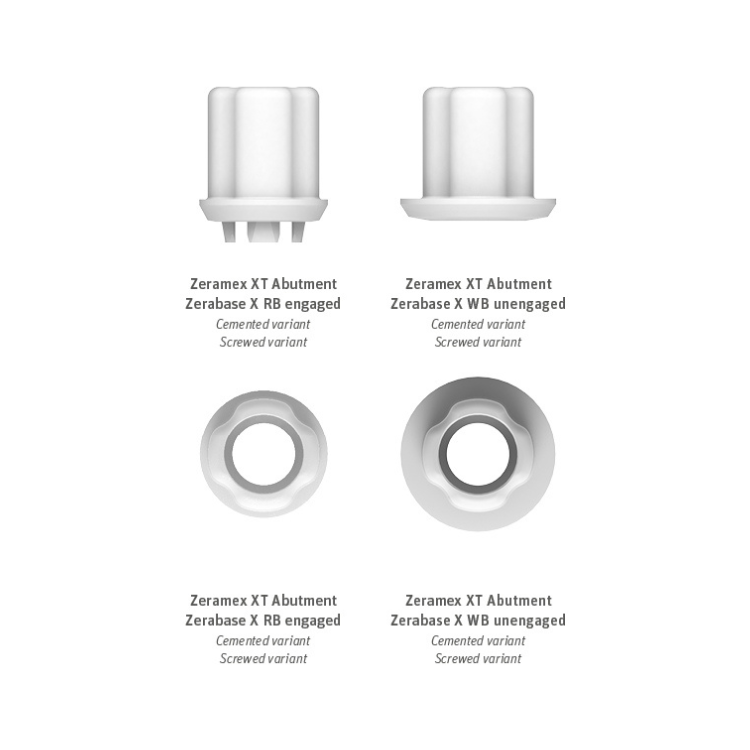

With Zerabase X and the digital workflow, you have the right abutment for an aesthetically demanding metal-free restoration in every case.

- Shorter and more slender design

- Enables larger angulations

- Available for SB / RB / WB

- Can be used variably (engaged - with interlocks / unengaged - without interlocks)

- Digital impression with scanbody possible

Case documentation: Completely digitally supplied, MDT Peter Hoelldampf

Ordering Process

> Take a digital impression. Impressions are taken digitally using an intraoral scanner (by scanning a scanbody) or by taking an impression of the patient with a master model which is then scanned.

> Create your desired design. Model a crown or an individual abutment as usual in your 3Shape or exocad software and create your desired design.

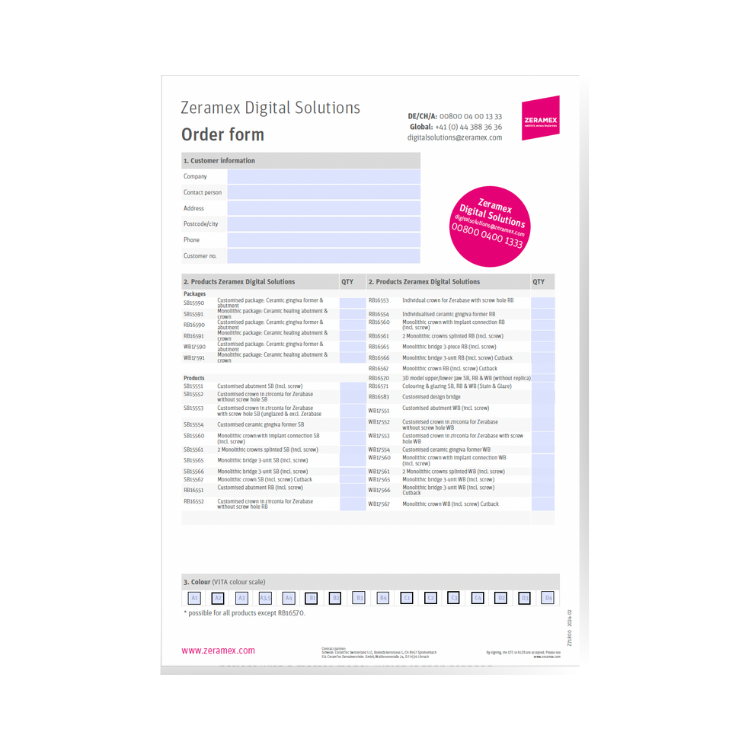

> Fill in the order form. Fill in the order form and save it on your computer.

> Send us your STL data with the completed order form via WeTransfer. Send us your digital data (STL file) and the completed order form.

> Production and delivery of your customised restoration. We produce the complete restoration including implant connection. You will receive the ready-to-use, precisely fitting prosthetic restoration of your choice within 10 days for insertion. On request, you can also receive a 3D-printed model.

Request price list via phone or email:

+41 (0) 44 388 36 36

00800 0400 1333 (toll-free in D/A/CH)

digitalsolutions@zeramex.com

Digital Workflow

The impression is taken using an intraoral scanner (a scanbody is scanned in; available for SB 3.5 mm, RB 4.2 mm or WB 5.5 mm) or using a master model which is then scanned in. The tightening torque for a scanbody is max. 5 Ncm.

CAD/CAM via exocad

Zeramex XT Exocad - Workflow (Zeramex Digital Solutions)

Zeramex XT Exocad - Import guide

Zeramex XT Exocad - CAD libraries

CAD/CAM via 3shape

Frequently Asked Questions

Is there a scanbody for each implant platform (SB/RB/WB)?

Yes, there is an individual scanbody for each implant diameter (SB/RB/WB).

Can the scanbodies be used multiple times?

Scanbodies that are used intraorally are single-use products. Scanbodies can be used several times in the laboratory.

How long does it take for the finished product to be delivered?

The finished product is usually delivered within 10 working days after approval of the STL data.

How many spans may a bridge have?

Bridges may have three spans.

Which angulations are permitted?

Angulations may be 20° to max. 30°. Angled screw channels are not permitted.

What material are implant restorations made of?

Implant restorations are made of yttrium-stabilised zirconium dioxide (Y-TZP). Flexural strength* of Y-TZP [MPa]: 1150士200. Fracture toughness [MPa√m] (KIC): > 9.5. The CTE value of Y-TZP is ~10.8 at 25-500°C.

*Measured according to DIN EN ISO

Do you have any questions about Zeramex Digital Solutions?

We are here to help you. Please fill out the following contact form.